ألياف طبيعية

| جزء من سلسلة عن |

| الألياف |

|---|

|

|

Agriculture Portal • Engineering Portal Category |

الألياف الطبيعية Natural fibers، هي ألياف تنتجها النباتات والحيوانات، والعمليات الجيولوجية.[1] يمكن استخدامها كعنصر ضمن المركبات، حيث يؤثر اتجاه الألياف على الخصائص.[2] كما يمكن تلبيدها في ألواح لصنع الورق أو اللباد.[3][4]

The earliest evidence of humans using fibers is the discovery of wool and dyed flax fibers found in a prehistoric cave in the Republic of Georgia that date back to 36,000 BP.[5][6] Natural fibers can be used for high-tech applications, such as composite parts for automobiles. Compared to composites reinforced with glass fibers, composites with natural fibers have advantages such as lower density, better thermal insulation, and reduced skin irritation. Further, unlike glass fibers, natural fibers can be broken down by bacteria once they are no longer in use.

Natural fibers are good sweat absorbents and can be found in a variety of textures. Cotton fibers made from the cotton plant, for example, produce fabrics that are light in weight, soft in texture, and which can be made in various sizes and colors. Clothes made of natural fibers such as cotton are often preferred over clothing made of synthetic fibers by people living in hot and humid climates.

الألياف النباتية

| التصنيف | الأنواع |

|---|---|

| ألياف البذور | The fibers collected from the seeds of various plants are known as seed fibers. |

| ألياف الأوراق | Fibers collected from the cells of a leaf are known as leaf fibers, for example, banana,[7] pineapple (PALF),[8] etc. |

| ألياف اللحاء | Bast fibers are collected from the outer cell layers of the plant's stem. These fibers are used for durable yarn, fabric, packaging, and paper. Some examples are flax, jute, kenaf, industrial hemp, ramie, rattan, and vine fibers.[9] |

| ألياف الفواكه | Fibers collected from the fruit of the plant, for example, coconut fiber (coir). |

| ألياف الساق | Fibers from the stalks of plants, e.g. straws of wheat, rice, barley, bamboo and straw.[7] |

الألياف الحيوانية

Animal fibers generally comprise proteins such as collagen, keratin and fibroin; examples include silk, sinew, wool, catgut, angora, mohair and alpaca.

- Animal hair (wool or hairs): Fiber or wool taken from animals or hairy mammals. e.g. sheep's wool, goat hair (cashmere, mohair), alpaca hair, horse hair, etc.

- Silk fiber: Fiber secreted by glands (often located near the mouth) of insects during the preparation of cocoons.

- Avian fiber: Fibers from birds, e.g. feathers and feather fiber.

الكايتين

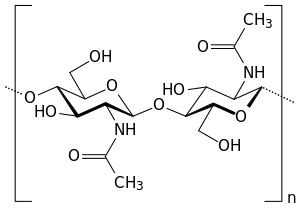

Chitin is the second most abundant natural polymer in the world, with collagen being the first. It is a “linear polysaccharide of β-(1-4)-2-acetamido-2-deoxy-D-glucose”.[10] Chitin is highly crystalline and is usually composed of chains organized in a β sheet. Due to its high crystallinity and chemical structure, it is insoluble in many solvents. It also has a low toxicity in the body and is inert in the intestines. Chitin also has antibacterial properties.[11]

In nature, pure chitin (100% acetylation) does not exist. It instead exists as a copolymer with chitin's deacetylated derivative, chitosan. When the acetylized composition of the copolymer is over 50% acetylated it is chitin.[12] This copolymer of chitin and chitosan is a random or block copolymer.[10]

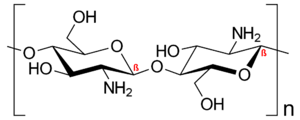

الكيتوزان

Chitosan is a deacetylated derivative of chitin. When the acetylized composition of the copolymer is below 50% it is chitosan.[12] Chitosan is a semicrystalline “polymer of β-(1-4)-2-amino-2-deoxy-D-glucose”.[10] One difference between chitin and chitosan is that chitosan is soluble in acidic aqueous solutions. Chitosan is easier to process that chitin, but it is less stable because it is more hydrophilic and has pH sensitivity. Due to its ease of processing, chitosan is used in biomedical applications.[11]

الكولاجين

Collagen is a structural protein, often referred to as “the steel of biological materials”.[13] There are multiple types of collagen: Type I (comprising skin, tendons and ligaments, vasculature and organs, as well as teeth and bone); Type II (a component in cartilage); Type III (often found in reticular fibers); and others. Collagen has a hierarchical structure, forming triple helices, fibrils, and fibers.[12]

الكراتين

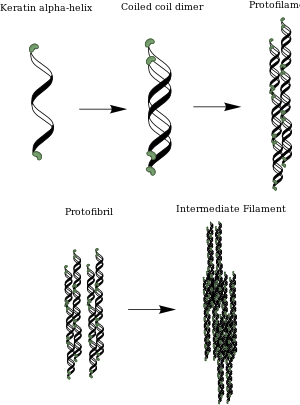

Keratin is a structural protein located at the hard surfaces in many vertebrates. Keratin has two forms, α-keratin and β-keratin, that are found in different classes of chordates. The naming convention for these keratins follows that for protein structures: alpha keratin is helical and beta keratin is sheet-like. Alpha keratin is found in mammalian hair, skin, nails, horn and quills, while beta keratin can be found in avian and reptilian species in scales, feathers, and beaks. The two different structures of keratin have dissimilar mechanical properties, as seen in their dissimilar applications. The relative alignment of the keratin fibrils has a significant impact on the mechanical properties. In human hair the filaments of alpha keratin are highly aligned, giving a tensile strength of approximately 200MPa. This tensile strength is an order of magnitude higher than human nails (20MPa), because human hair’s keratin filaments are more aligned.[10]

الخصائص

مقارنة لخصائص الألياف الاصطناعية والطبيعية من حيث الصلابة والقوة.[10]

| المادة | الألياف | معامل المرونة (GPa) | القوة (MPa) |

|---|---|---|---|

| الأوتار | الكولاجين | 1.50 | 150 |

| العظام | الكولاجين | 20.0 | 160 |

| الهيكل الخارجي لسرطان الطين (الرطب) | الكايتين | 0.48 | 30 |

| الهيكل الخارجي للجمبري (الرطب) | الكايتين | 0.55 | 28 |

| حوافر الأبقار | الكراتين | 0.40 | 16 |

| الصوف | الكراتين | 0.50 | 200 |

عامل الرطوبة

The presence of water plays a crucial role in the mechanical behavior of natural fibers. Hydrated, biopolymers generally have enhanced ductility and toughness. Water plays the role of a plasticizer, a small molecule easing passage of polymer chains and in doing so increasing ductility and toughness. When using natural fibers in applications outside of their native use, the original level of hydration must be taken into account. For example when hydrated, the Young’s Modulus of collagen decreases from 3.26 to 0.6 GPa and becomes both more ductile and tougher. Additionally the density of collagen decreases from 1.34 to 1.18 g/cm^3.[10]

التطبيقات

الاستخدام الصناعي

Of industrial value are four animal fibers, wool, silk, camel hair, and angora as well as four plant fibers, cotton, flax, hemp, and jute. Dominant in terms of scale of production and use is cotton for textiles.[14]

مركبات الألياف الطبيعية

Natural fibers are also used in composite materials, much like synthetic or glass fibers. These composites, called biocomposites, are a natural fiber in a matrix of synthetic polymers.[1] One of the first biofiber-reinforced plastics in use was a cellulose fiber in phenolics in 1908.[1] Usage includes applications where energy absorption is important, such as insulation, noise absorbing panels, or collapsable areas in automobiles.[15]

مركب نانوي

Nanocomposites are desirable for their mechanical properties. When fillers in a composite are at the nanometer length scale, the surface to volume ratio of the filler material is high, which influences the bulk properties of the composite more compared to traditional composites. The properties of these nanosized elements is markedly different than that of its bulk constituent.

المواد الحيوية والتوافق الحيوي

Natural fibers often show promise as biomaterials in medical applications. Chitin is notable in particular and has been incorporated into a variety of uses. Chitin based materials have also been used to remove industrial pollutants from water, processed into fibers and films, and used as biosensors in the food industry.[16] Chitin has also been used several of medical applications. It has been incorporated as a bone filling material for tissue regeneration, a drug carrier and excipient, and as an antitumor agent.[17] Insertion of foreign materials into the body often triggers an immune response, which can have a variety of positive or negative outcomes depending on the bodies response to the material. Implanting something made from naturally synthesized proteins, such as a keratin based implant, has the potential to be recognized as natural tissue by the body. This can lead either to integration in rare cases where the structure of the implant promotes regrowth of tissue with the implant forming a superstructure or degradation of the implant in which the backbones of the proteins are recognized for cleavage by the body.[16][17]

انظر أيضاً

المصادر

- ^ أ ب ت John, Maya Jacob; Thomas, Sabu (2008-02-08). "Biofibres and biocomposites". Carbohydrate Polymers. 71 (3): 343–364. doi:10.1016/j.carbpol.2007.05.040.

- ^ Sousa, Fangueiro, Raul Manuel Esteves de; Sohel, Rana (2016-02-11). Natural fibres : advances in science and technology towards industrial applications : from science to market. ISBN 9789401775137. OCLC 938890984.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Doelle, Klaus (2013-08-25). "New Manufacturing Method for Paper Filler and Fiber Material" (in الإنجليزية). doi:10.2172/1091089. OSTI 1091089.

{{cite journal}}: Cite journal requires|journal=(help) - ^ Gillick, T. J. (1959-08-01). "Natural and Synthetic Fiber Felts". Industrial & Engineering Chemistry. 51 (8): 904–907. doi:10.1021/ie50596a025. ISSN 0019-7866.

- ^ Balter, M (2009). "Clothes Make the (Hu) Man". Science. 325 (5946): 1329. doi:10.1126/science.325_1329a. PMID 19745126.

- ^ Kvavadze, E; Bar-Yosef, O; Belfer-Cohen, A; Boaretto, E; Jakeli, N; Matskevich, Z; Meshveliani, T (2009). "30,000-Year-Old Wild Flax Fibers". Science. 325 (5946): 1359. Bibcode:2009Sci...325.1359K. doi:10.1126/science.1175404. PMID 19745144. S2CID 206520793.

- ^ أ ب Fuqua, Michael A.; Huo, Shanshan; Ulven, Chad A. (2012-07-01). "Natural Fiber Reinforced Composites". Polymer Reviews. 52 (3): 259–320. doi:10.1080/15583724.2012.705409. ISSN 1558-3724. S2CID 138171705.

- ^ Todkar, Santosh (2019-10-01). "Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites". Composites Part B. 174: 106927. doi:10.1016/j.compositesb.2019.106927. ISSN 1359-8368.

- ^ Summerscales, John; Dissanayake, Nilmini P. J.; Virk, Amandeep S.; Hall, Wayne (2010-10-01). "A review of bast fibres and their composites. Part 1 – Fibres as reinforcements" (PDF). Composites Part A. 41 (10): 1329–1335. doi:10.1016/j.compositesa.2010.06.001. hdl:10026.1/9928.

- ^ أ ب ت ث ج ح خ خطأ استشهاد: وسم

<ref>غير صحيح؛ لا نص تم توفيره للمراجع المسماة:2 - ^ أ ب Rinaudo, Marguerite (2006-07-01). "Chitin and chitosan: Properties and applications". Progress in Polymer Science. 31 (7): 603–632. doi:10.1016/j.progpolymsci.2006.06.001.

- ^ أ ب ت خطأ استشهاد: وسم

<ref>غير صحيح؛ لا نص تم توفيره للمراجع المسماة:1 - ^ C., FUNG, Y. (1981-01-01). BIOMECHANICS : mechanical properties of living tissues (1). SPRINGER. ISBN 978-1475717525. OCLC 968439866.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ "Fibers, 1. Survey". ULLMANN'S ENCYCLOPEDIA OF INDUSTRIAL CHEMISTRY. Wiley-VCH. 2011. doi:10.1002/14356007.a10_451.pub2. ISBN 978-3527306732.

{{cite encyclopedia}}: Cite uses deprecated parameter|authors=(help) - ^ Heng, Jerry Y. Y.; Pearse, Duncan F.; Thielmann, Frank; Lampke, Thomas; Bismarck, Alexander (2007-01-01). "Methods to determine surface energies of natural fibres: a review". Composite Interfaces. 14 (7–9): 581–604. doi:10.1163/156855407782106492. ISSN 0927-6440. S2CID 97667541.

- ^ أ ب Mohanty, A; Misra, M; Henrichsen, G (March 2000). "Biofibres, biodegradable polymers and biocomposites:An overview". Macromolecular Materials and Engineering. 276: 1–24. doi:10.1002/(SICI)1439-2054(20000301)276:1<1::AID-MAME1>3.0.CO;2-W.

- ^ أ ب Temenoff, J.; Mikos, A (2008). Biomaterials: The Intersection of Biology and Materials Science. Pearson/Prentice Hall.