مفاعل مهد الحصى

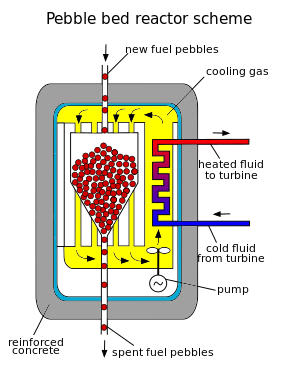

The pebble-bed reactor (PBR) is a design for a graphite-moderated, gas-cooled nuclear reactor. It is a type of very-high-temperature reactor (VHTR), one of the six classes of nuclear reactors in the Generation IV initiative. The basic design of pebble-bed reactors features spherical fuel elements called pebbles. These tennis ball-sized pebbles are made of pyrolytic graphite (which acts as the moderator), and they contain thousands of micro-fuel particles called TRISO particles. These TRISO fuel particles consist of a fissile material (such as 235U) surrounded by a ceramic layer coating of silicon carbide for structural integrity and fission product containment. In the PBR, thousands of pebbles are amassed to create a reactor core, and are cooled by a gas, such as helium, nitrogen or carbon dioxide, that does not react chemically with the fuel elements. Other coolants such as FLiBe[مطلوب توضيح] (a molten salt[بحاجة لمصدر]) have also been suggested for implementation with pebble fuelled reactors.[بحاجة لمصدر]

Some examples of this type of reactor are claimed to be passively safe;[1] that is, it removes the need for redundant, active safety systems. Because the reactor is designed to handle high temperatures, it can cool by natural circulation and still survive in accident scenarios, which may raise the temperature of the reactor to 1,600 °C. Because of its design, its high temperatures allow higher thermal efficiencies than possible in traditional nuclear power plants (up to 50%) and has the additional feature that the gases do not dissolve contaminants or absorb neutrons as water does, so the core has less in the way of radioactive fluids.

The concept was first suggested by Farrington Daniels in the 1940s, said to have been inspired by the innovative design of the benghazi burner by British desert troops in WWII, but commercial development did not take place until the 1960s in the German AVR reactor by Rudolf Schulten.[2] This system was plagued with problems and political and economic decisions were made to abandon the technology.[3] The AVR design was licensed to South Africa as the PBMR and China as the HTR-10, the latter currently has the only such design in operation. In various forms, other designs are under development by MIT, University of California at Berkeley, General Atomics (U.S.), the Dutch company Romawa B.V., Adams Atomic Engines, Idaho National Laboratory, X-energy and Kairos Power.

Pebble-bed design

A pebble-bed power plant combines a gas-cooled core[4] and a novel packaging of the fuel that dramatically reduces complexity while improving safety.[5]

The uranium, thorium or plutonium nuclear fuels are in the form of a ceramic (usually oxides or carbides) contained within spherical pebbles a little smaller than the size of a tennis ball and made of pyrolytic graphite, which acts as the primary neutron moderator. The pebble design is relatively simple, with each sphere consisting of the nuclear fuel, fission product barrier, and moderator (which in a traditional water reactor would all be different parts). Simply piling enough pebbles together in a critical geometry will allow for criticality.

The pebbles are held in a vessel, and an inert gas (such as helium, nitrogen or carbon dioxide) circulates through the spaces between the fuel pebbles to carry heat away from the reactor. Pebble-bed reactors need fire-prevention features to keep the graphite of the pebbles from burning in the presence of air if the reactor wall is breached, although the flammability of the pebbles is disputed. Ideally, the heated gas is run directly through a turbine. However, if the gas from the primary coolant can be made radioactive by the neutrons in the reactor, or a fuel defect could still contaminate the power production equipment, it may be brought instead to a heat exchanger where it heats another gas or produces steam. The exhaust of the turbine is quite warm and may be used to warm buildings or chemical plants, or even run another heat engine.

Much of the cost of a conventional, water-cooled nuclear power plant is due to cooling system complexity. These are part of the safety of the overall design, and thus require extensive safety systems and redundant backups. A water-cooled reactor is generally dwarfed by the cooling systems attached to it. Additional issues are that the core irradiates the water with neutrons causing the water and impurities dissolved in it to become radioactive and that the high-pressure piping in the primary side becomes embrittled and requires continual inspection and eventual replacement.

In contrast, a pebble-bed reactor is gas-cooled, sometimes at low pressures. The spaces between the pebbles form the "piping" in the core. Since there is no piping in the core and the coolant contains no hydrogen, embrittlement is not a failure concern. The preferred gas, helium, does not easily absorb neutrons or impurities. Therefore, compared to water, it is both more efficient and less likely to become radioactive.

خصائص الأمان

Pebble-bed reactors have an advantage over conventional light-water reactors in operating at higher temperatures. A technical advantage is that some designs are throttled by temperature, not by control rods. The reactor can be simpler because it does not need to operate well at the varying neutron profiles caused by partially withdrawn control rods.[بحاجة لمصدر]

Pebble-bed reactors are also capable of using fuel pebbles made from different fuels in the same basic design of reactor (though perhaps not at the same time). Proponents claim that some kinds of pebble-bed reactors should be able to use thorium, plutonium and natural unenriched uranium, as well as the customary enriched uranium. There is a project in progress to develop pebbles and reactors that use MOX fuel, that mixes uranium with plutonium from either reprocessed fuel rods or decommissioned nuclear weapons.[بحاجة لمصدر]

In most stationary pebble-bed reactor designs, fuel replacement is continuous. Instead of shutting down for weeks to replace fuel rods, pebbles are placed in a bin-shaped reactor. A pebble is recycled from the bottom to the top about ten times over a few years, and tested each time it is removed. When it is expended, it is removed to the nuclear-waste area, and a new pebble inserted.

When the nuclear fuel increases in temperature, the rapid motion of the atoms in the fuel causes an effect known as Doppler broadening. The fuel then sees a wider range of relative neutron speeds. Uranium-238, which forms the bulk of the uranium in the reactor, is much more likely to absorb fast or epithermal neutrons at higher temperatures. This reduces the number of neutrons available to cause fission, and reduces the power of the reactor. Doppler broadening therefore creates a negative feedback: as fuel temperature increases, reactor power decreases. All reactors have reactivity feedback mechanisms, but the pebble-bed reactor is designed so that this effect is very strong. Also, it is automatic and does not depend on any kind of machinery or moving parts. If the rate of fission increases, temperature will increase and Doppler broadening will occur, decreasing the rate of fission. This negative feedback creates passive control of the reaction process.

Because of this, and because the pebble-bed reactor is designed for higher temperatures, the reactor will passively reduce to a safe power-level in an accident scenario. This is the main passive safety feature of the pebble-bed reactor, and it distinguishes the pebble-bed design (as well as most other very-high-temperature reactors) from conventional light-water reactors, which require active safety controls.

The reactor is cooled by an inert, fireproof gas, so it cannot have a steam explosion as a light-water reactor can. The coolant has no phase transitions—it starts as a gas and remains a gas. Similarly, the moderator is solid carbon; it does not act as a coolant, move, or have phase transitions (i.e., between liquid and gas) as the light water in conventional reactors does. Convection of the gas driven by the heat of the pebbles ensures that the pebbles are passively cooled[بحاجة لمصدر].

A pebble-bed reactor thus can have all of its supporting machinery fail, and the reactor will not crack, melt, explode or spew hazardous wastes. It simply goes up to a designed "idle" temperature, and stays there. In that state, the reactor vessel radiates heat, but the vessel and fuel spheres remain intact and undamaged. The machinery can be repaired or the fuel can be removed. These safety features were tested (and filmed) with the German AVR reactor.[6] All the control rods were removed, and the coolant flow was halted. Afterward, the fuel balls were sampled and examined for damage - there was none.

PBRs are intentionally operated above the 250 °C annealing temperature of graphite, so that Wigner energy is not accumulated. This solves a problem discovered in an infamous accident, the Windscale fire. One of the reactors at the Windscale site in England (not a PBR) caught fire because of the release of energy stored as crystalline dislocations (Wigner energy) in the graphite. The dislocations are caused by neutron passage through the graphite. Windscale had a program of regular annealing in place to release accumulated Wigner energy, but since the effect was not anticipated during the construction of the reactor, and since the reactor was cooled by ordinary air in an open cycle, the process could not be reliably controlled, and led to a fire. The second generation of UK gas-cooled reactors, the AGRs, also operate above the annealing temperature of graphite.

Berkeley professor Richard A. Muller has called pebble-bed reactors "in every way ... safer than the present nuclear reactors".[7]

الحاوية

Most pebble-bed reactor designs contain many reinforcing levels of containment to prevent contact between the radioactive materials and the biosphere:

- Most reactor systems are enclosed in a containment building designed to resist aircraft crashes and earthquakes.

- The reactor itself is usually in a two-meter-thick-walled room with doors that can be closed, and cooling plenums that can be filled from any water source.

- The reactor vessel is usually sealed.

- Each pebble, within the vessel, is a 60 ميليمتر (2.4 in) hollow sphere of pyrolytic graphite.

- A wrapping of fireproof silicon carbide

- Low density porous pyrolytic carbon, high density nonporous pyrolytic carbon

- The fission fuel is in the form of metal oxides or carbides

Pyrolytic graphite is the main structural material in these pebbles. It sublimates at 4000 °C, more than twice the design temperature of most reactors. It slows neutrons very effectively, is strong, inexpensive, and has a long history of use in reactors and other very high temperature applications. For example, pyrolytic graphite is also used, unreinforced, to construct missile reentry nose-cones and large solid rocket nozzles.[8] Its strength and hardness come from anisotropic crystals of carbon.

Pyrolytic carbon can burn in air when the reaction is catalyzed by a hydroxyl radical (e.g., from water).[بحاجة لمصدر] Infamous examples include the accidents at Windscale and Chernobyl—both graphite-moderated reactors. However, all pebble-bed reactors are cooled by inert gases to prevent fire. All pebble designs also have at least one layer of silicon carbide that serves as a fire break as well as a seal.

إنتاج الوقود

All kernels are precipitated from a sol-gel, then washed, dried and calcined. U.S. kernels use uranium carbide, while German (AVR) kernels use uranium dioxide. German-produced fuel-pebbles release about three orders of magnitude (1000 times) less radioactive gas than the U.S. equivalents, due to these different construction methods.[9][10]

انتقدات تصميم المفاعل

الگرافيت القابل للاحتراق

The most common criticism of pebble-bed reactors is that encasing the fuel in combustible graphite poses a hazard. When the graphite burns, fuel material could be carried away in smoke from the fire. Since burning graphite requires oxygen, the fuel kernels are coated with a layer of silicon carbide, and the reaction vessel is purged of oxygen. While silicon carbide is strong in abrasion and compression applications, it does not have the same strength against expansion and shear forces. Some fission products such as xenon-133 have a limited absorbance in carbon, and some fuel kernels could accumulate enough gas to rupture the silicon carbide layer.[بحاجة لمصدر] Even a cracked pebble will not burn without oxygen, but the fuel pebble may not be rotated out and inspected for months, leaving a window of vulnerability.

بناء الحاوية

Some designs for pebble-bed reactors lack a containment building, potentially making such reactors more vulnerable to outside attack and allowing radioactive material to spread in the case of an explosion. However, the current emphasis on reactor safety means that any new design will likely have a strong reinforced concrete containment structure.[11] Also, any explosion would most likely be caused by an external factor, as the design does not suffer from the steam explosion-vulnerability of some water-cooled reactors.

معالجة النفايات

Since the fuel is contained in graphite pebbles, the volume of radioactive waste is much greater, but contains about the same radioactivity when measured in becquerels per kilowatt-hour. The waste tends to be less hazardous and simpler to handle.[بحاجة لمصدر] Current US legislation requires all waste to be safely contained, therefore pebble-bed reactors would increase existing storage problems. Defects in the production of pebbles may also cause problems. The radioactive waste must either be safely stored for many human generations, typically in a deep geological repository, reprocessed, transmuted in a different type of reactor, or disposed of by some other alternative method yet to be devised. The graphite pebbles are more difficult to reprocess due to their construction,[بحاجة لمصدر] which is not true of the fuel from other types of reactors.

حادث 1986

In West Germany, in 1986, an accident involved a jammed pebble that was damaged by the reactor operators when they were attempting to dislodge it from a feeder tube (see THTR-300 section). This accident released radiation into the surrounding area, and probably was one reason for the shutdown of the research program by the West German government.

تقرير 2008

In 2008, a report[12][13] about safety aspects of the AVR reactor in Germany and some general features of pebble-bed reactors have drawn attention. The claims are under contention.[14] Main points of discussion are

- No possibility to place standard measurement equipment in the pebble-bed core, i.e. pebble bed = black box

- Contamination of the cooling circuit with metallic fission products (Sr-90, Cs-137) due to the insufficient retention capabilities of fuel pebbles for metallic fission products. Even modern fuel elements do not sufficiently retain strontium and caesium.

- improper temperatures in the core (more than 200 °C above calculated values)

- necessity of a pressure retaining containment

- unresolved problems with dust formation by pebble friction (dust acts as a mobile fission product carrier, if fission products escape the fuel particles)

Rainer Moormann, author of the report, requests for safety reasons a limitation of average hot helium temperatures to 800 °C minus the uncertainty of the core temperatures (which is at present at about 200 °C).

The pebble-bed reactor has an advantage over traditional reactors in that the gases do not dissolve contaminants or absorb neutrons as water does, so the core has less in the way of radioactive fluids. However, as mentioned above, the pebbles generate graphite particulates that can blow through the coolant loop carrying fission products, if fission products escape the TRISO particles.

التاريخ

The first suggestion for this type of reactor came in 1947 from Prof. Dr. Farrington Daniels at Oak Ridge, who also created the name "pebble-bed reactor".[15] The concept of a very simple, very safe reactor, with a commoditized nuclear fuel was developed by Professor Dr. Rudolf Schulten in the 1950s. The crucial breakthrough was the idea of combining fuel, structure, containment, and neutron moderator in a small, strong sphere. The concept was enabled by the realization that engineered forms of silicon carbide and pyrolytic carbon were quite strong, even at temperatures as high as 2000 °C (3600 °F). The natural geometry of close-packed spheres then provides the ducting (the spaces between the spheres) and spacing for the reactor core. To make the safety simple, the core has a low power density, about 1/30 the power density of a light water reactor.

ألمانيا

AVR

مفاعل الثوريوم عالي الحرارة

التصميمات المختلفة

الصين

جنوب أفريقيا

محركات آدمز الذرية

إكس-إنرجي

انظر أيضاً

- Gas turbine modular helium reactor

- Generation IV reactor

- Next Generation Nuclear Plant

- Nuclear fuel

- Nuclear safety

- Rainer Moormann

- Very high temperature reactor

المصادر

- ^ Kadak, A.C. (2005). "A future for nuclear energy: pebble bed reactors, Int. J. Critical Infrastructures, Vol. 1, No. 4, pp.330–345" (PDF).

- ^ Association of German Engineers (VDI), the Society for Energy Technologies (publ.) (1990). AVR - Experimental High-Temperature Reactor, 21 Years of Successful Operation for A Future Energy Technology. Association of German Engineers (VDI), The Society for Energy Technologies. pp. 9–23. ISBN 3-18-401015-5.

- ^ NGNP Point Design – Results of the Initial Neutronics and Thermal-Hydraulic Assessments During FY-03 Archived 2006-06-14 at the Wayback Machine pg 20

- ^ Pebble Bed Modular Reactor - What is PBMR? Archived 2015-05-03 at the Wayback Machine

- ^ How the PBMR Fueling System Works Archived مارس 9, 2008 at the Wayback Machine

- ^ [1] Archived يونيو 13, 2006 at the Wayback Machine

- ^ Richard A. Muller (2008). Physics for Future Presidents. Norton Press. p. 170. ISBN 978-0-393-33711-2.

- ^ "Fabrication of pyrolytic graphite rocket nozzle components". Retrieved 2009-10-06.

- ^ Key Differences in the Fabrication of US and German TRISO-COATED Particle Fuel, and their Implications on Fuel Performance Free, accessed 4/10/2008

- ^ D. A. Petti; J. Buongiorno; J. T. Maki; R. R. Hobbins; G. K. Miller (2003). "Key differences in the fabrication, irradiation and high temperature accident testing of US and German TRISO-coated particle fuel, and their implications on fuel performance". Nuclear Engineering and Design. 222 (2–3): 281–297. doi:10.1016/S0029-5493(03)00033-5.

- ^ NRC: Speech - 027 - "Regulatory Perspectives on the Deployment of High Temperature Gas-Cooled Reactors in Electric and Non-Electric Energy Sectors" Archived مايو 3, 2015 at the Wayback Machine

- ^ Rainer Moormann (2008). "A safety re-evaluation of the AVR pebble bed reactor operation and its consequences for future HTR concepts". Forschungszentrum Jülich, Zentralbibliothek, Verlag. hdl:2128/3136. Berichte des Forschungszentrums Jülich JUEL-4275.

{{cite journal}}: Cite journal requires|journal=(help) - ^ Rainer Moormann (1 April 2009). "PBR safety revisited". Nuclear Engineering International. Archived from the original on 30 May 2012. Retrieved 2009-04-02.

- ^ Albert Koster (29 May 2009). "Pebble Bed Reactor - Safety in perspective". Nuclear Engineering International. Archived from the original on 26 June 2010.

- ^ "ORNL Review Vol. 36, No. 1, 2003 - Nuclear Power and Research Reactors". Ornl.gov. Archived from the original on 2013-07-01. Retrieved 2013-09-05.

وصلات خارجية

- IAEA HTGR Knowledge Base

- AVR, experimental high-temperature reactor : 21 years of successful operation for a future energy technology ISBN 3-18-401015-5

- High Temperature Reactor 2006 Conference, Sandton, South Africa

- MIT page on Modular Pebble Bed Reactor

- Research on innovative reactors in Jülich

- Differences in American and German TRISO-coated fuels

- معمل آيدهو الوطني- الولايات المتحدة

- Conceptual Design of a Very High Temperature Pebble-Bed Reactor 2003

- NGNP Point Design - Results of the Initial Neutronics and Thermal-Hydraulic Assessments During FY-03, Rev. 1, September 2003

- Next Generation Nuclear Plant (NGNP) Project – Preliminary Assessment Of Two Possible Designs, March 21 – 25, 2004

- The Next Generation Nuclear Plant – Insights Gained from the INEEL Point Design Studies, August 25 – September 3, 2004

- Computation of Dancoff Factors for Fuel Elements Incorporating Randomly Packed TRISO Particles, January 2005

- جنوب أفريقيا

- Coalition Against Nuclear Energy South Africa

- Eskom

- PBMR (Pty.) Ltd.

- Pebble Bed Modular Reactor - PBMR - Home

- Atomic Energy in South Africa

- Earthlife Africa: Nuclear Energy Costs the Earth campaign

- Steve Thomas (2005), "The Economic Impact of the Proposed Demonstration Plant for the Pebble Bed Modular Reactor Design", PSIRU, University of Greenwich, UK

- NPR (April 17, 2006) NPR: South Africa Invests in Nuclear Power

- جميع الصفحات التي تحتاج تنظيف

- مقالات بالمعرفة تحتاج توضيح from January 2020

- Articles with unsourced statements from January 2020

- Articles with unsourced statements from August 2019

- Articles with unsourced statements from January 2019

- Articles with unsourced statements from February 2009

- Articles with unsourced statements from May 2008

- Articles with hatnote templates targeting a nonexistent page

- Pages with empty portal template

- Pebble bed reactors

- أنواع مفاعلات الطاقة النووية