مكثف (مخبر)

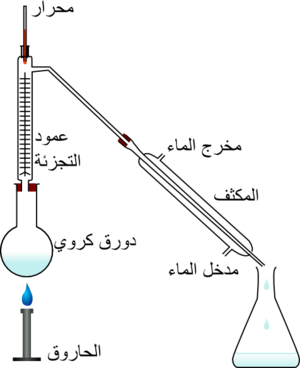

المكثف في المخبر هو قطعة من الأدوات الزجاجية المخبرية ويستخدم في تبريد البخار أو الموائع الساخنة. يتكون المكثف من أنبوب زجاجي كبير يحتوي على أنبوب زجاجي أصغر من سابقه يمتد على كامل طوله حيث يمر ضمنه المائع الساخن.

تكيف نهاية الأنبوب الزجاجي الداخلي عادة وفق وصلات زجاجية مصقولة بحيث يسهل تثبيتها مع الأدوات الزجاجية الأخرى. تترك النهاية العليا عادة مفتوحة للضغط الجوي، أو تهوّى باستخدام صنبور (bubbler) أو أنبوب تجفيف (Drying tube) لمنع دخول الماء أو الأكسيجين.

ويكون الأنبوب الزجاجي الخارجي عادة مزود بفتحتين ناتئتين يمكن وصلهما لتمرير سائل تبريد، إما أن يستعمل ماء الصنبور العادي أو يستعمل مزيج من الماء ومضاد التجمد. وللحصول على أفضل مردود، وللحفاظ على تدرج حراري مباشر وصحيح لتقليل خطر الصدمة الحرارية التي تصيب الأداة الزجاجية المجاورة، يدخل المبرد من جهة نهاية المكثف ويخرج من الجهة الأخرى. ويمكن توصيل عدة مكثفات على التسلسل حين لا يفيد تدفق سائل التبريد في تبريد السطح الداخلي للمكثف.

أمثلة للعمليات

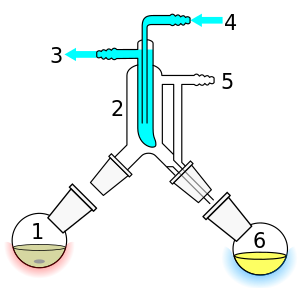

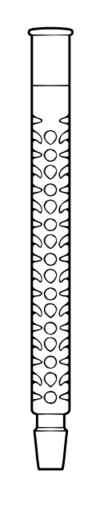

Condensers are often used in reflux, where the hot solvent vapors of a liquid being heated are cooled and allowed to drip back.[1] This reduces the loss of solvent allowing the mixture to be heated for extended periods. Condensers are used in distillation to cool the hot vapors, condensing them into liquid for separate collection. For fractional distillation, an air or Vigreux condenser is usually used to slow the rate at which the hot vapors rise, giving a better separation between the different components in the distillate. For microscale distillation, the apparatus includes the pot, and the condenser fused into one piece, which reduces the holdup volume, and obviates the need for ground glass joints preventing contamination by grease and precluding leaks.

| Simple distillation with Minimal Added Theoretical Plates | [Legend] |

|---|---|

|

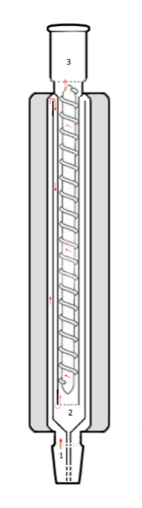

Shown in a cutaway view, blue indicating cooling flow and bath, red and yellow indicating heat. White areas in the short Vigreux section, 3, above boiling flask 2, and in Liebig condenser 5, and in vacuum take-off adapter 10, and receiving flask 8 represent the path through which vapor flows to the Liebig condenser (2→3→5) and the condensate flows from the condenser to a pre-weighed collection flask (5→10→8). Per usual, trapezoids represent matching ground glass joints allowing tight seals of apparatus parts. Impure liquid 15 is placed in boiling flask 2, and on a hotplate-stirrer (1, 13) equipped with silicone oil bath 14, and heated with stirring (11, 12) or other otherwise prevented from bumping (see text). Vapor rises vertically, coming first in contact with the Vigreux indentations in distillation head 3, and when the reflux reaches the height of the downspout of the adapter (point of bulb of thermometer 4), vapor proceeds downward to contact Liebig condenser, 5, chilled by fluid flow through ports 6 and 7. As the warm gases boiled from flask 2 come into contact with the cold surface of condenser 5, the gaseous volatile changes state to liquid (condenses), and proceeds to the right, through the drip tip of take-off adapter 10 into collection flask 8. which is correspondingly cooled in bath 16 to prevent loss of product evaporation. After distillation is complete (often not to complete dryness of 15), the apparatus can be disassembled, a rough yield determined, and analysis for identity and purity as described above. Likewise,a as noted, distillation at ambient pressure has port 9 is attached to a drying tube while in a vacuum distillation, port 9 allows attachment of the vacuum pump. |

(finger indentations)

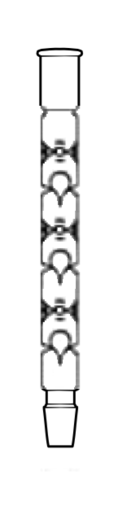

(floating inverted teardrops)

(concentric tube,

rod-and-spiral)

الأنواع المبردة بالهواء

الأنواع المبردة بالسوائل

مكثف ليبگ

مقالة مفصلة: مكثف ليبگ

مقالة مفصلة: مكثف ليبگ

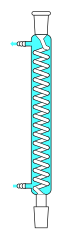

مكثف آلين

The Allihn condenser or "bulb condenser" or simply "reflux condenser" is named after Felix Richard Allihn (1854–1915).[2][3] The Allihn condenser consists of a long glass tube with a water jacket. A series of bulbs on the tube increases the surface area upon which the vapor constituents may condense. Ideally suited for laboratory-scale refluxing.

اقرأ أيضا

المراجع

- ^ Zhi Hua (Frank) Yang (2005). "Design methods for [industrial] reflux condensers". Chemical Processing (online). Retrieved 2015-02-02.

- ^ See:

- Allihn, F. (1886) "Rückflusskühler für analytische Extractions-Apparate" (Reflux condenser for analytical extraction apparatuses), Chemiker Zeitung (Chemist's Newspaper), 10 (4) : 52.

- Allihn, F. (1886) "Rückflusskühler für analytische Extractionsapparate" (Reflux condenser for analytical extraction apparatuses), Zeitschrift für analytische Chemie, 25 : 36.

- ^ Sella, Andrea (2010). "Allihn's Condenser". Chemistry World. 2010 (5): 66.