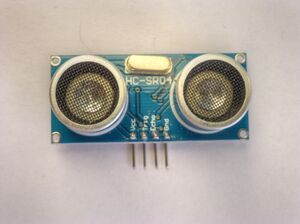

مجس فوق صوتي

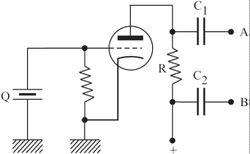

المجسات فوق الصوتية Ultrasonic sensors، أو التواترات فوق الصوتية هي تواترات الأمواج فوق الصوتية التي تفوق تواتر الأصوات التي تتحسس بها أذن الإنسان والتي هي دون الـ 20000هرتز. ويدرسها فرع من الفيزياء يعرف باسم فوق الصوتيات ultrasonics. تولِّد مولِّدات الأمواج فوق الصوتية الحديثة أمواجاً يبلغ تواترها بضعة غيغا هرتز (1GHz = 109 Hz)، وذلك عن طريق تحويل تيارات متناوبة عالية التواتر إلى اهتزازات ميكانيكية. ويتم عادة الكشف عن هذه الأمواج باستخدام بلورات كهرضغطية piezoelectric أو بوسائل ضوئية، حيث يمكن بالإفادة من انعراج الضوء جعل هذه الأمواج مرئية.

طريقة العمل

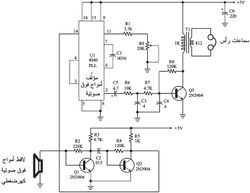

يلتقط اللاقط الأمواج فوق الصوتية ويحولها إلى اهتزازات كهربائية، فيضخمها الترانزستوران Q1 و Q2، ثم تنتقل إلى الدارة التكاملية U1 فتدخلها عبر المربط 14، تقوم الدارة التكاملية بمقارنة الطور بين الإشارة الملتقطة وإشارة تولِّدها الدارة التكاملية يمكن التحكم بتواترها بفضل مجزئ الكمون R9، وتعطي الدارة تواتراً يساوي الفرق بين التواتر الملتقط والتواتر المولّد وذلك عند المربط 2. يقوم الترانزستور Q3 بتضخيم إشارة الفرق، وتنتقل الإشارة عبر المحول T1 إلى سمّاعات بصورة تواتر مسموع.[1]

لعلم فوق الصوتيات تطبيقات عديدة في مجالات الفيزياء والكيمياء والتقانة والطب. فقد استخدمت الأمواج فوق الصوتية منذ أمد بعيد لتوفير الاتصالات تحت الماء وللكشف عن الأجسام الغاطسة تحته كالغواصات، فيما يسمى بأجهزة السونار SONAR، وهي أجهزة تشبه الرادار في عملها إلا أنها تستخدم أمواجاً فوق صوتية لأداء مهمتها. كما تعد أجهزة السونار أجهزة أساسية لتوفير سلامة الملاحة البحرية.

الترجام

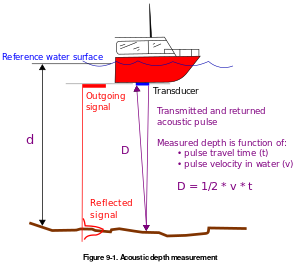

تقدير الأعماق

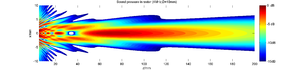

It involves transmitting acoustic waves into water and recording the time interval between emission and return of a pulse; the resulting time of flight, along with knowledge of the speed of sound in water, allows determining the distance between sonar and target. This information is then typically used for navigation purposes or in order to obtain depths for charting purposes. Distance is measured by multiplying half the time from the signal's outgoing pulse to its return by the speed of sound in the water, which is approximately 1.5 kilometres per second [T÷2×(4700 feet per second or 1.5 kil per second )] For precise applications of echosounding, such as hydrography, the speed of sound must also be measured typically by deploying a sound velocity probe into the water. Echo sounding is effectively a special purpose application of sonar used to locate the bottom. Since a traditional pre-SI unit of water depth was the fathom, an instrument used for determining water depth is sometimes called a fathometer. The first practical fathometer was invented by Herbert Grove Dorsey and patented in 1928.[2]

الاستخدام الطبي

Medical ultrasonic transducers (probes) come in a variety of different shapes and sizes for use in making cross-sectional images of various parts of the body. The transducer may be used in contact with the skin, as in fetal ultrasound imaging, or inserted into a body opening such as the rectum or vagina. Clinicians who perform ultrasound-guided procedures often use a probe positioning system to hold the ultrasonic transducer.[3]

Compared to other medical imaging modalities, ultrasound has several advantages. It provides images in real-time, is portable, and can consequently be brought to the bedside. It is substantially lower in cost than other imaging strategies and does not use harmful ionizing radiation. Drawbacks include various limits on its field of view, the need for patient cooperation, dependence on patient physique, difficulty imaging structures obscured by bone, air or gases,[note 1] and the necessity of a skilled operator, usually with professional training. Owing to these drawbacks, novel wearable ultrasound implementations are gaining popularity. These miniature devices continuously monitor vitals and alert at the emergence of early signs of abnormality.[4][5]

الاستخدام الصناعي

وتستخدم الأمواج فوق الصوتية في الفيزياء لتحديد خواص المواد كالانضغاطية compressibility، والمرونة elasticity، ونسب الحرارات النوعية specific heat ratios. كما تستخدم الأمواج فوق الصوتية في الكيمياء لإنتاج مستحلبات emulsions متجانسة كالمستعملة في صنع أفلام التصوير، وكذلك للكشف عن التشقُّقات في الصفائح وغيرها. وقد استخدمت الأمواج فوق الصوتية التي تقع تواتراتها في مجال الـ GHz لصنع «مجهر» صوتي يمكنه تمييز أبعاد من رتبة الميكرون. وتؤدي الأمواج السطحية التي تقع تواتراتها في المجال فوق الصوتي والمعروفة اختصاراً بـ SAW أي Surface Acoustic Waves دوراً مهماً في تجهيزات التحكُّم الإلكترونية.

Ultrasonic sensors can detect the movement of targets and measure the distance to them in many automated factories and process plants. Sensors can have an on or off digital output for detecting the movement of objects, or an analog output proportional to distance. They can sense the edge of the material as part of a web guiding system.

Ultrasonic sensors are widely used in cars as parking sensors to aid the driver in reversing into parking spaces. They are being tested for a number of other automotive uses including ultrasonic people detection and assisting in autonomous UAV navigation.[بحاجة لمصدر]

Because ultrasonic sensors use sound rather than light for detection, they work in applications where photoelectric sensors may not. Ultrasonics is a great solution for clear object detection and for liquid level measurement, applications that photoelectrics struggle with because of target translucence. As well, target color or reflectivity do not affect ultrasonic sensors, which can operate reliably in high-glare environments.

Passive ultrasonic sensors may be used to detect high-pressure gas or liquid leaks, or other hazardous conditions that generate ultrasonic sound. In these devices, ultrasound from the transducer (microphone) is converted down to the human hearing range (Audible Sound = 20 Hz to 20 kHz).

High-power ultrasonic emitters are used in commercially available ultrasonic cleaning devices. An ultrasonic transducer is affixed to a stainless steel pan which is filled with a solvent (frequently water or isopropanol). An electrical square wave feeds the transducer, creating sound in the solvent strong enough to cause cavitation.

Ultrasonic technology has been used for multiple cleaning purposes. One of which that been gaining a decent amount of traction in the past decade is ultrasonic gun cleaning.

In ultrasonic welding and ultrasonic wire bonding, plastics and metals are joining using vibrations created by power ultrasonic transducers.

Ultrasonic testing is also widely used in metallurgy and engineering to evaluate corrosion, welds, and material defects using different types of scans.

Notes

- ^ It is for this reason that the person subjected to ultrasound of organs that can contain quantities of air or gas, such as the stomach, intestine and bladder, must follow a food preparation designed to reduce their quantity: specific diet and supplements for the intestine and intake of non-carbonated water to fill the bladder; sometimes, during the examination, it may be required to fill the stomach with non-carbonated water.

المصادر

- ^ أحمد حصري. "القصدير". الموسوعة العربية. Retrieved 2012-03-29.

- ^ "Echo Sounding / Early Sound Methods". National Oceanic & Atmospheric Administration (NOAA). NOAA Central Library. 2006.

In answer to the need for a more accurate depth registering device, Dr. Herbert Grove Dorsey, who later joined the C&GS, devised a visual indicating device for measuring relatively short time intervals and by which shoal and deep depths could be registered. In 1925, the C&GS obtained the very first Fathometer, designed and built by the Submarine Signal Company.

- ^ SCHNEIDER, MICHEL (1999). "Characteristics of SonoVue™". Echocardiography. Wiley. 16 (s1): 743–746. doi:10.1111/j.1540-8175.1999.tb00144.x. ISSN 0742-2822. PMID 11175217. S2CID 73314302.

- ^ Srivastav, A.; Bhogi, K.; Mandal, S.; Sharad, M. (Aug 2019). "An Adaptive Low-Complexity Abnormality Detection Scheme for Wearable Ultrasonography". IEEE Transactions on Circuits and Systems. 66 (8): 1466–1470. Bibcode:2019ITCSE..66.1466S. doi:10.1109/TCSII.2018.2881612. S2CID 117391787.

- ^ "Wearable Ultrasounds Poised to Revolutionize Healing and Pain Management Healthcare Market" (Press release). Jun 2021.

وصلات خارجية

- Ultrasonic Acoustic Sensing Brown University

- Laser Ultrasonic Sensor Streamlines Papermaking Process, Lawrence Berkeley Lab, Dan Krotz

- Ultrasonic Flaw Detection for Technicians, Chapter 2, 3rd ed., 2004 by J. C. Drury (~5 pages)

- Measure distance using the ultrasonic sensor

- Ultra Technology More uniform fibre distribution in paper with ultrasonics in the paper machine wet end.

- Ultrasound transducer entry in the public domain NCI Dictionary of Cancer Terms

- Ultrasonic Transmitter and Receiver circuit diagram

- Ultrasonic Sensors for Industry

- Siemens Ultrasonic Level Measurement

- Choosing an Ultrasonic Sensor for Proximity or Distance Measurement Sensors Magazine.

- Transducer Info Center.

- Outdoor Ultrasonic Sensors